The Science Behind Fire Dampers: How They Work to Contain Fire & Smoke

Introduction: Why Understanding Fire Dampers Matters

Most people know that fire dampers play a vital role in preventing the spread of fire and smoke, but few understand how they actually work. In the world of building safety, every second counts — and understanding the science behind fire dampers can help duty holders, facilities managers, and engineers appreciate why proper testing and maintenance are so critical.

This article breaks down the mechanics and materials behind these essential devices, explaining in clear, practical terms how fire dampers function within ventilation systems to contain a fire and save lives.

What Is a Fire Damper?

A fire damper is a passive fire protection device installed within a building’s ductwork system. Its purpose is to prevent flames and smoke from spreading through ventilation shafts when a fire occurs. By automatically closing when heat is detected, it forms a physical barrier that maintains compartmentation — a principle central to fire safety design.

When we talk about the science behind fire dampers, we’re referring to the thermodynamics, material properties, and mechanical systems that make this rapid response possible. Let’s explore how that works.

The Core Mechanism: Fusible Links and Heat Activation

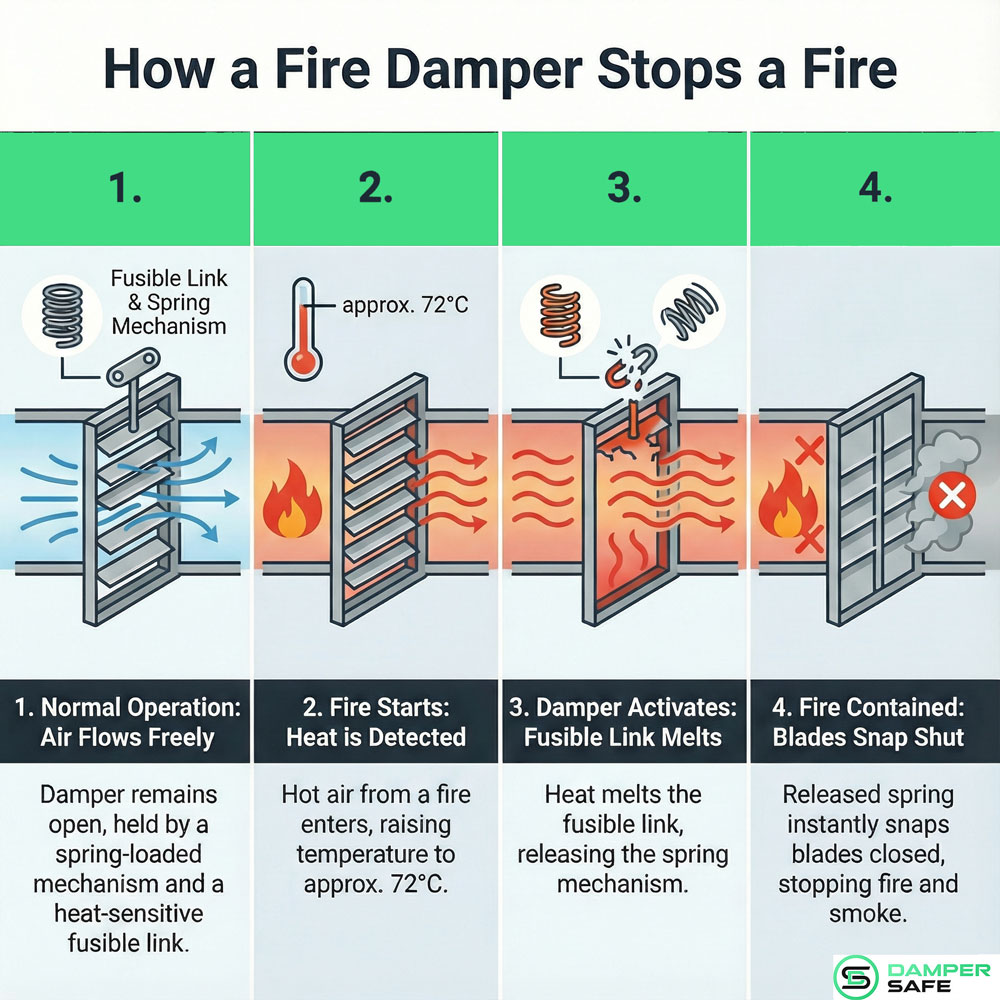

The most traditional type of fire damper operates using a fusible link — a small metal component designed to melt at a specific temperature, typically around 72°C. This temperature is high enough to avoid accidental activation but low enough to react quickly in the event of a fire.

When heat from a fire rises through the ductwork, the fusible link melts, releasing a spring-loaded mechanism that snaps the damper blades shut. This immediate closure is what prevents hot gases and smoke from being drawn through the ventilation system.

In essence, the science behind fire dampers is about precision and timing. Each fusible link must melt consistently and completely at the designated temperature to ensure the damper performs exactly when needed.

Modern Advancements: Motorised and Smoke Control Dampers

While fusible links remain widely used, many buildings now rely on motorised or electrically actuated fire dampers. These modern systems integrate directly with fire alarm controls or smoke detection systems, closing automatically when a signal is triggered.

Motorised fire dampers use electric actuators that provide both reliability and real-time monitoring. In some systems, sensors can confirm whether each damper is open, closed, or obstructed — vital information during a fire event or building inspection.

This integration of electronics and mechanical engineering showcases the evolving science behind fire dampers: combining traditional thermally activated systems with smart technology for faster, more reliable responses.

The Role of Airflow and Pressure

Ventilation systems are designed to keep air circulating efficiently throughout a building, but in the event of a fire, this same airflow can feed oxygen to the flames and spread smoke quickly. The science behind fire dampers lies in counteracting that process.

When a damper closes, it disrupts the airflow and creates a sealed barrier within the ductwork. This containment helps maintain pressure differentials between rooms and fire compartments, ensuring that smoke and toxic gases don’t move freely through the ventilation system.

By balancing airflow and isolation, fire dampers work in harmony with fire doors, smoke vents, and suppression systems to protect both structure and occupants.

Materials and Design Engineering

The effectiveness of any fire damper depends heavily on its materials and design. Most dampers are made from galvanised or stainless steel, chosen for their strength, heat resistance, and durability. Blade-style dampers use overlapping metal fins that interlock tightly when closed, while curtain-style dampers use flexible sheets that drop into position when triggered.

Advanced materials, including fire-resistant coatings and corrosion-resistant finishes, enhance performance over time — particularly in environments with high humidity or chemical exposure.

To learn more about innovations shaping the industry, read our blog Fire Damper Innovations and New Technologies.

Testing: The Science in Practice

Understanding the science behind fire dampers is only part of the equation — the other half is ensuring they work when needed. Every damper must be tested at least once every 12 months, in line with DW145 standards and BS 9999. Testing confirms that blades close fully, fusible links function correctly, and access panels allow for safe inspection.

Our article Fire Damper Testing Costs Explained breaks down what affects testing prices and why budgeting properly for compliance is essential for long-term safety.

Integration with Fire Safety Systems

Fire dampers don’t work in isolation. They form part of a larger building safety ecosystem, linking with alarms, smoke detectors, and HVAC controls. In integrated systems, dampers can be programmed to respond to temperature or smoke sensors, automatically sealing off zones while redirecting airflow to aid evacuation and firefighting efforts.

These systems reflect the modern science behind fire dampers: real-time automation that enhances protection through intelligent communication between safety components.

Real-World Applications: From Offices to Hospitals

The science behind fire dampers applies across all building types — from office blocks and schools to hospitals and data centres. In healthcare environments, for example, dampers protect vulnerable patients during staged evacuations, while in commercial offices, they protect escape routes and stairwells where hundreds of people may need to exit simultaneously.

For sector-specific guidance, see our post Fire Damper Compliance Across UK Industry Sectors.

Conclusion: Engineering You Can Trust

Understanding the science behind fire dampers reveals just how critical these systems are to modern fire protection. From the precision melting of fusible links to the advanced automation of motorised actuators, every component is engineered to react instantly and save lives.

However, even the most advanced systems depend on proper installation, access, and testing. At Damper Safe Ltd, our engineers ensure every damper operates at peak performance through expert inspection, maintenance, and reporting.

To learn more or schedule professional fire damper testing, contact Damper Safe Ltd today.

For official technical guidance, visit the Health and Safety Executive Fire Safety resource.